Our Services

What sets us apart from the competition is the vast range of services we offer. We will help you all the way through from planning to completion. First, we start by taking the time to understand your project, review drawings if you have any, and offer suggestions when required. We also provide the service to create the necessary drawings for your project if these are not available.

Once we finalise the design, we will help you choose the appropriate material and service to suit your budget and needs. From then onwards, we will continue with the required steps according to the service to finish the project with the best possible outcome to satisfy your expectations.

Contact us for more information or any work related to the below-mentioned services!

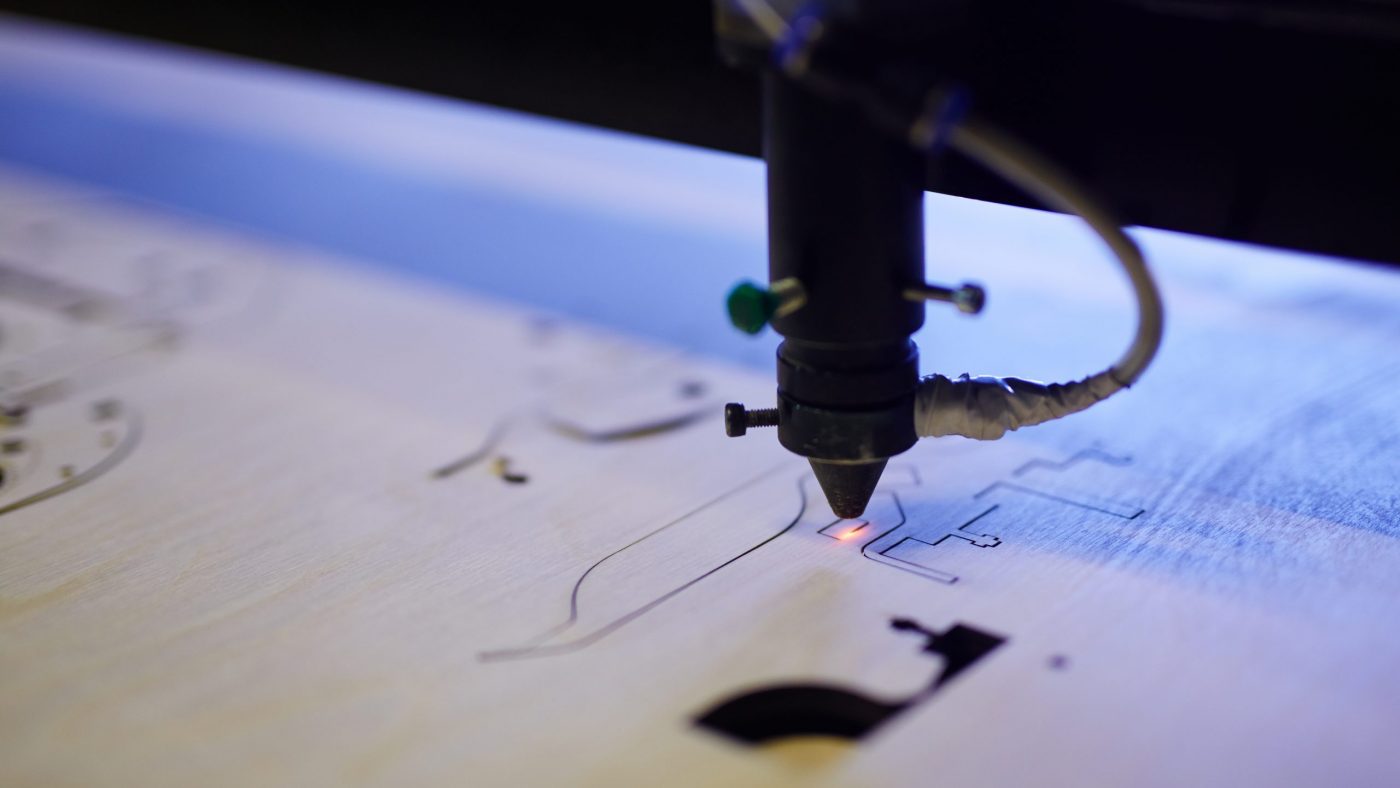

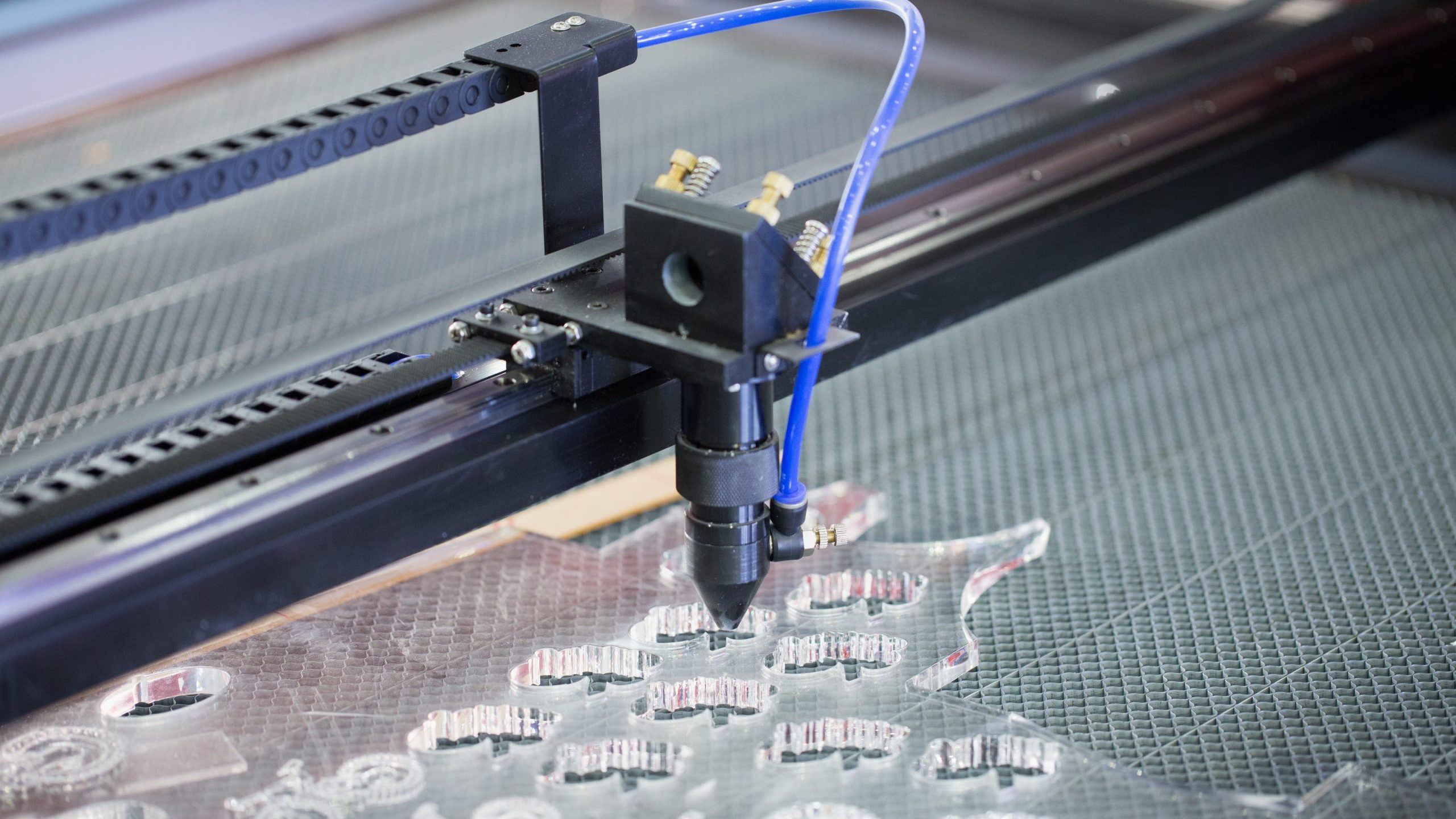

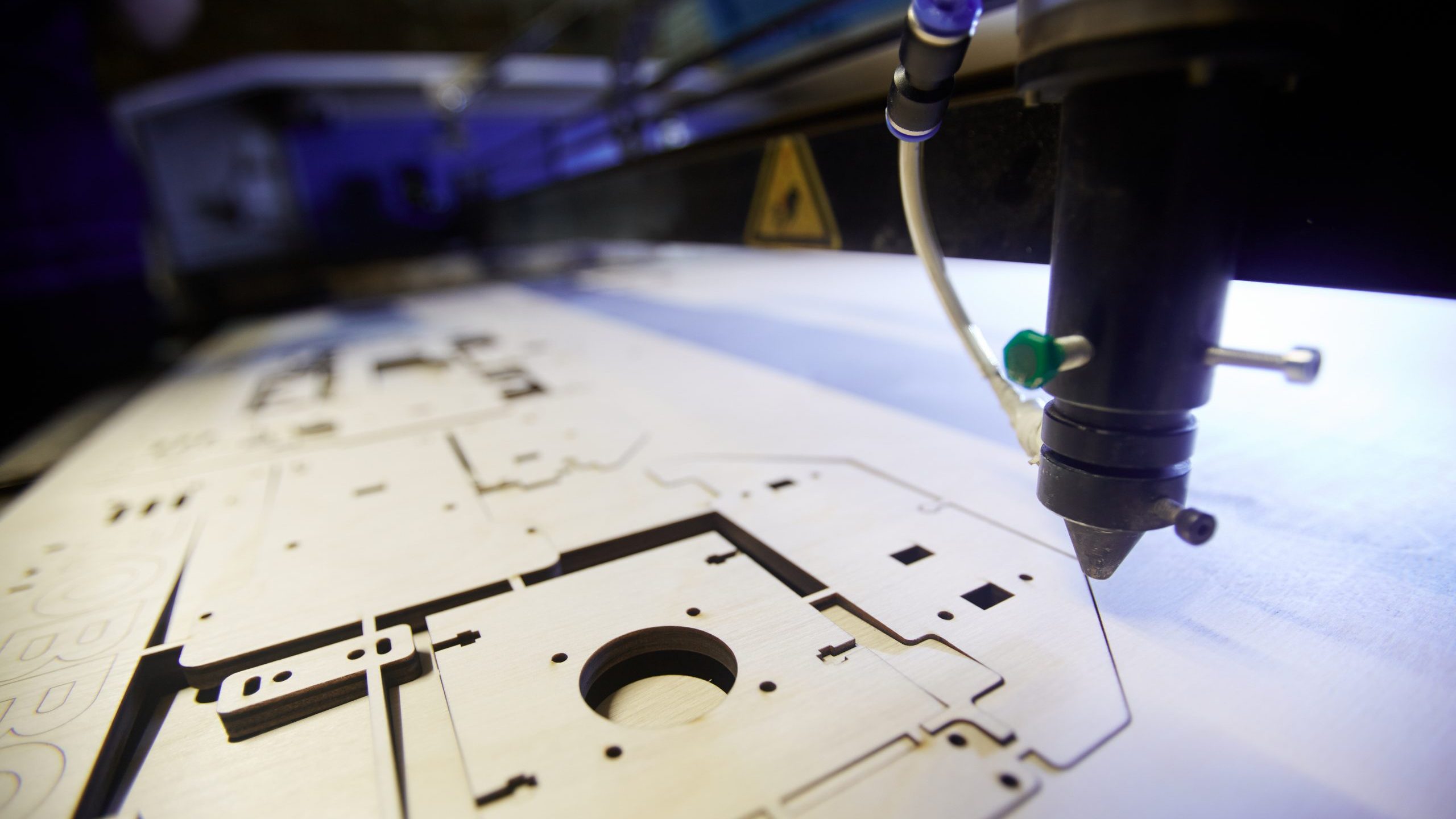

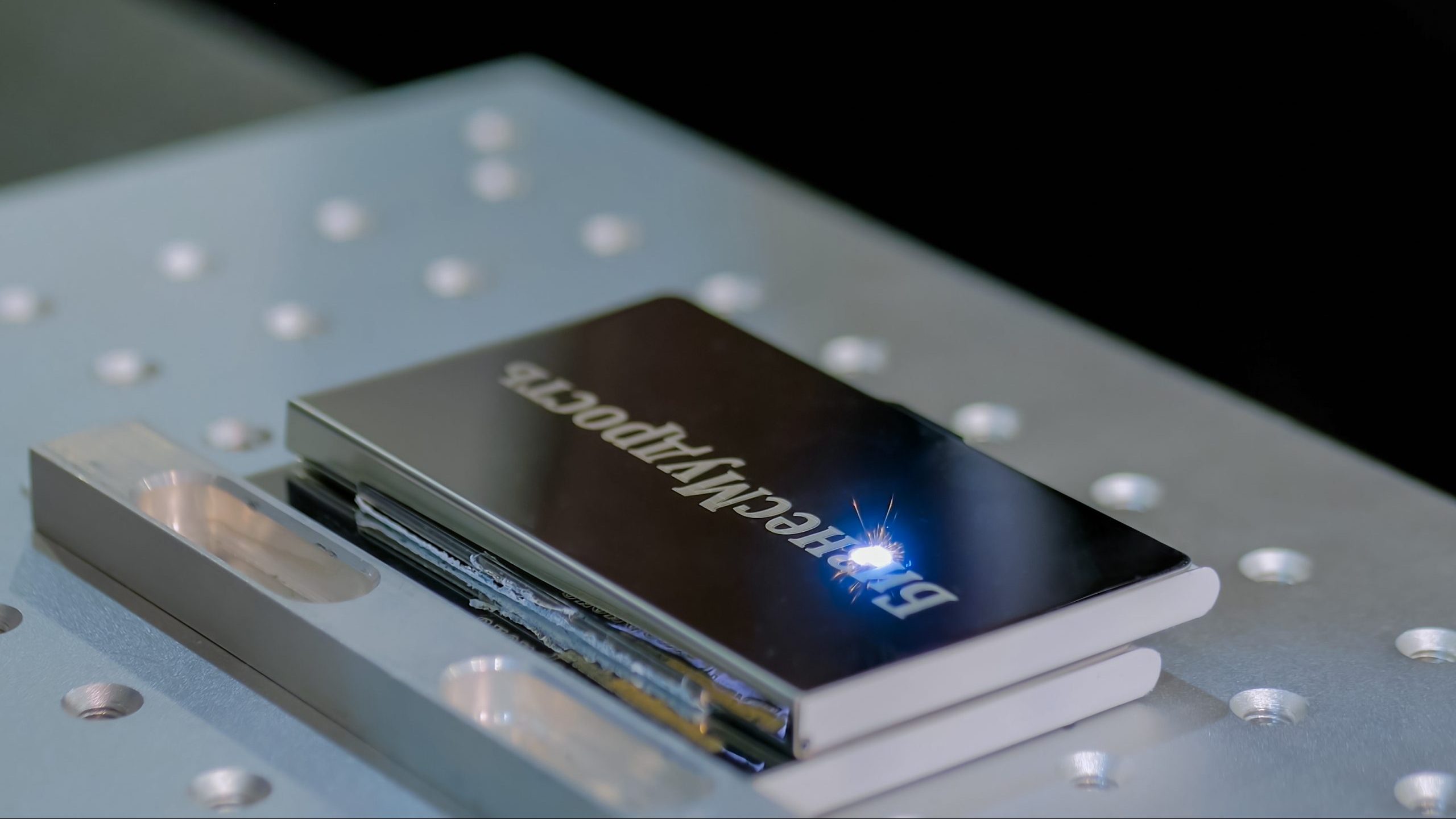

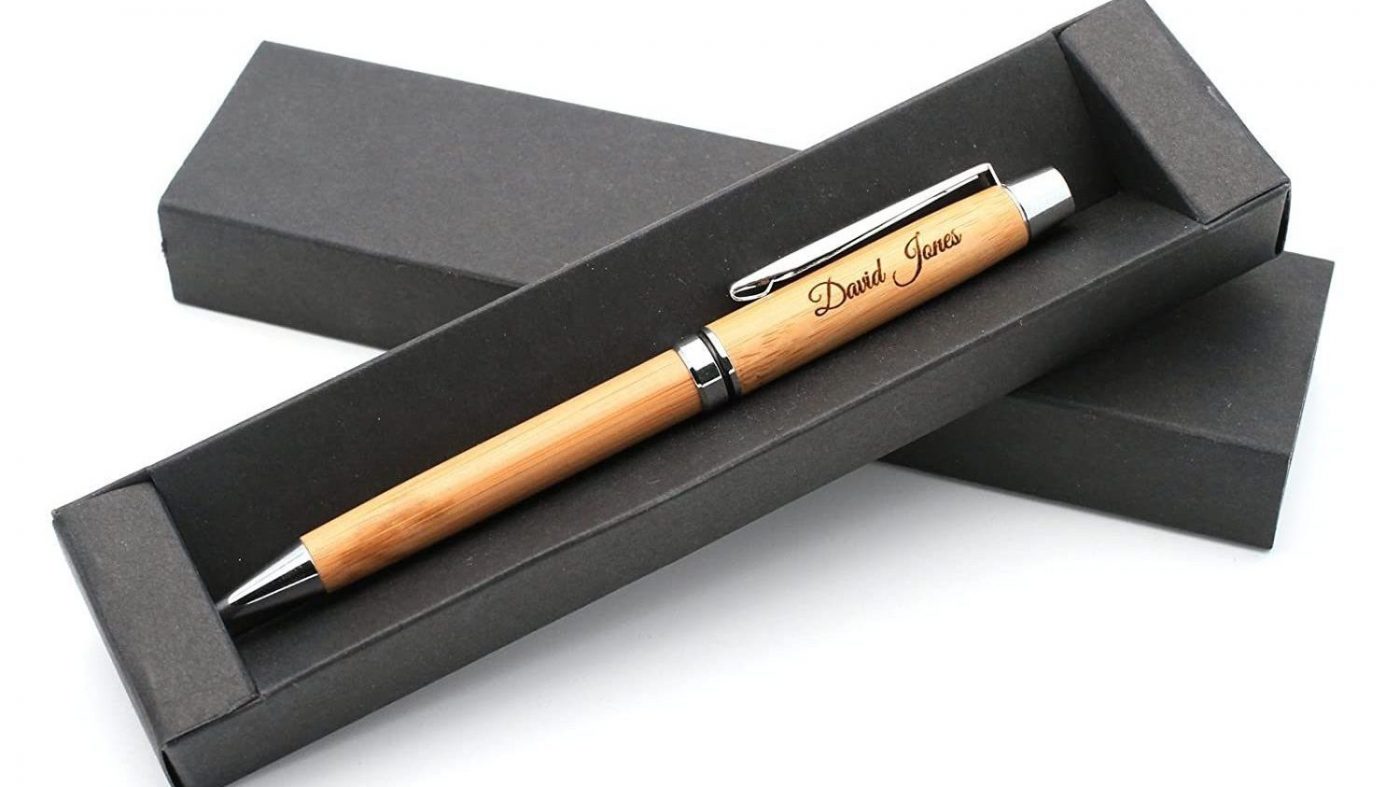

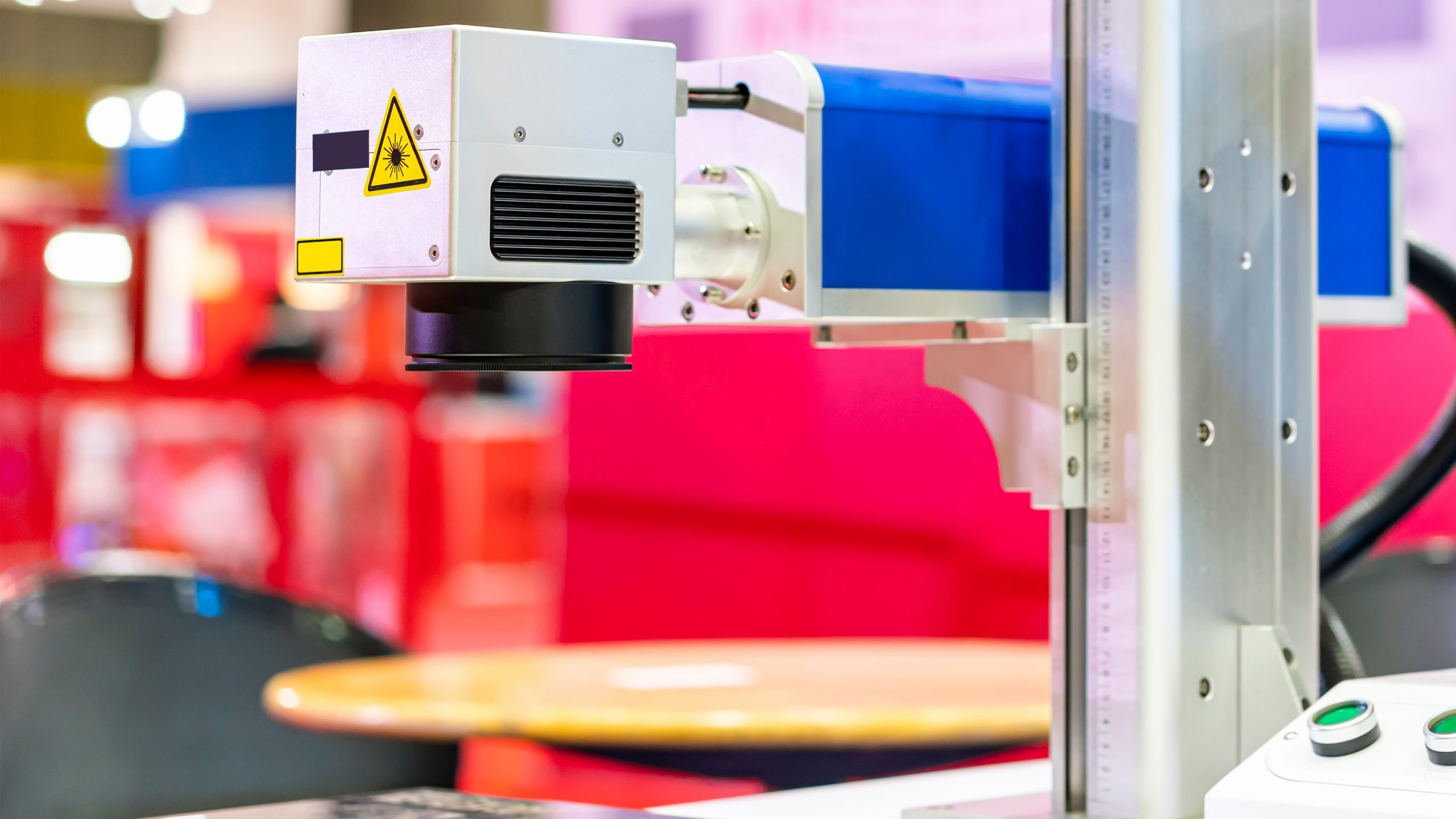

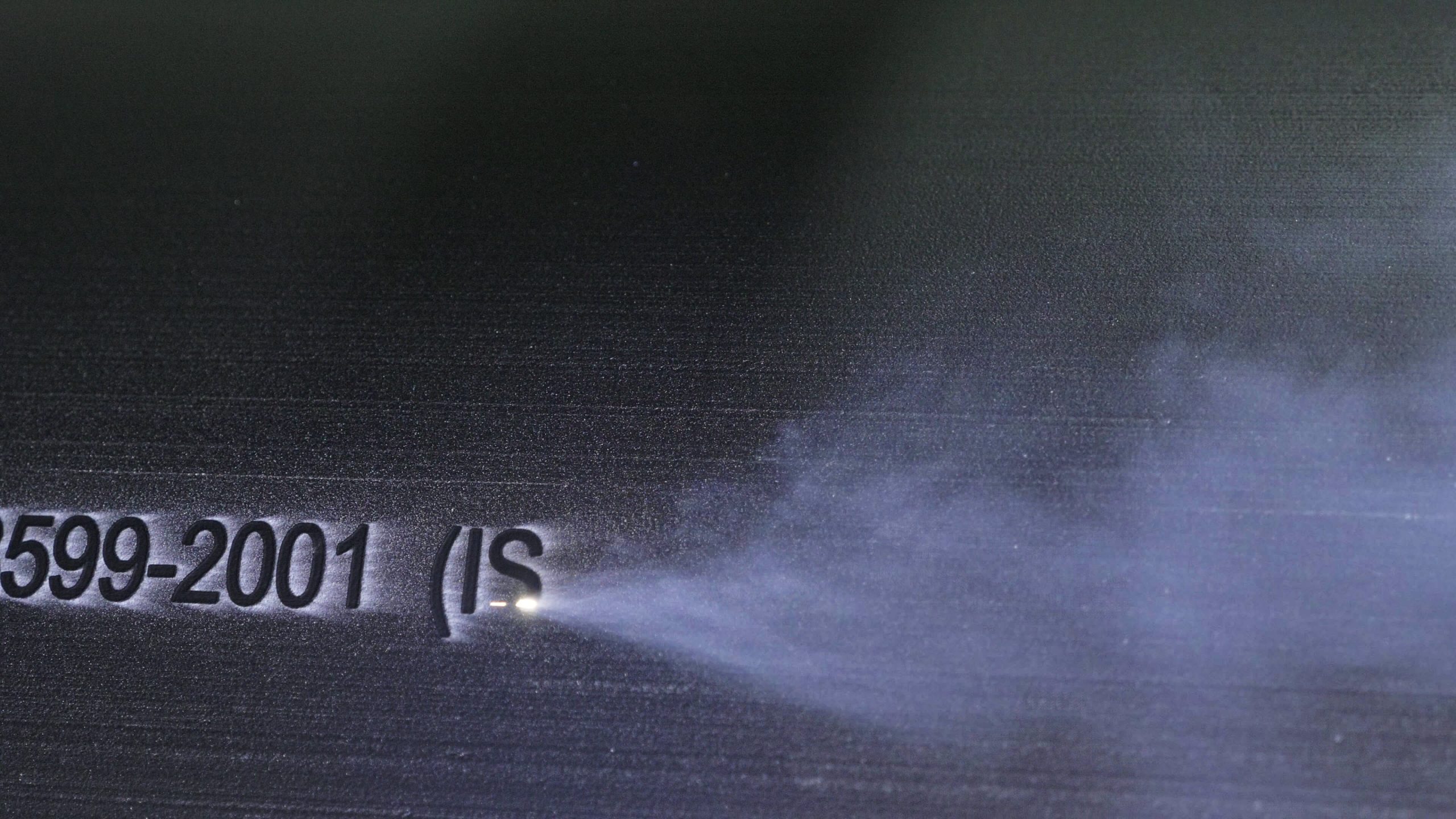

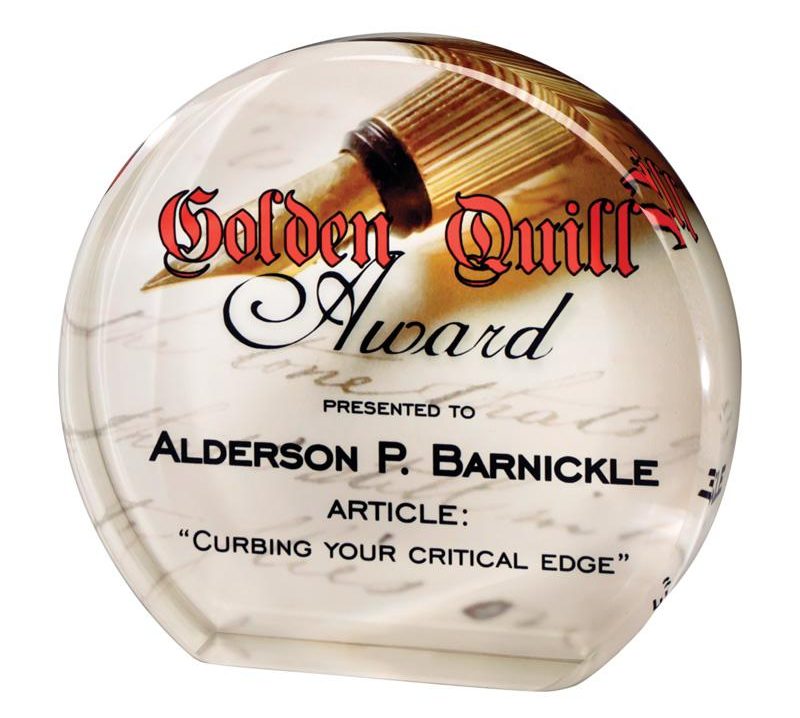

Laser Engraving & Cutting

We offer a very high-quality laser engraving & cutting service using two different types of machines.

C02 Laser can cut and engrave areas up to 1500mm x 1000mm. This laser machine is used mainly for glass, wood, acrylic, perspex, and fabric such as leather.

Fiber Laser can cut areas up to 150 x 150mm and engrave working areas up to 300 x 300mm. Such laser is used mainly for engraving metals such as stainless steel, iron, gold, silver, etc. Regarding cutting thickness, fiber lasers can cut material up to 1.2mm thick.

Some of the products we engrave or cut using these machines are champaign glasses, wine glasses, whisky glasses, signs/house names, glass awards, acrylic awards, wooden plaques & awards, wooden biros and craft projects.

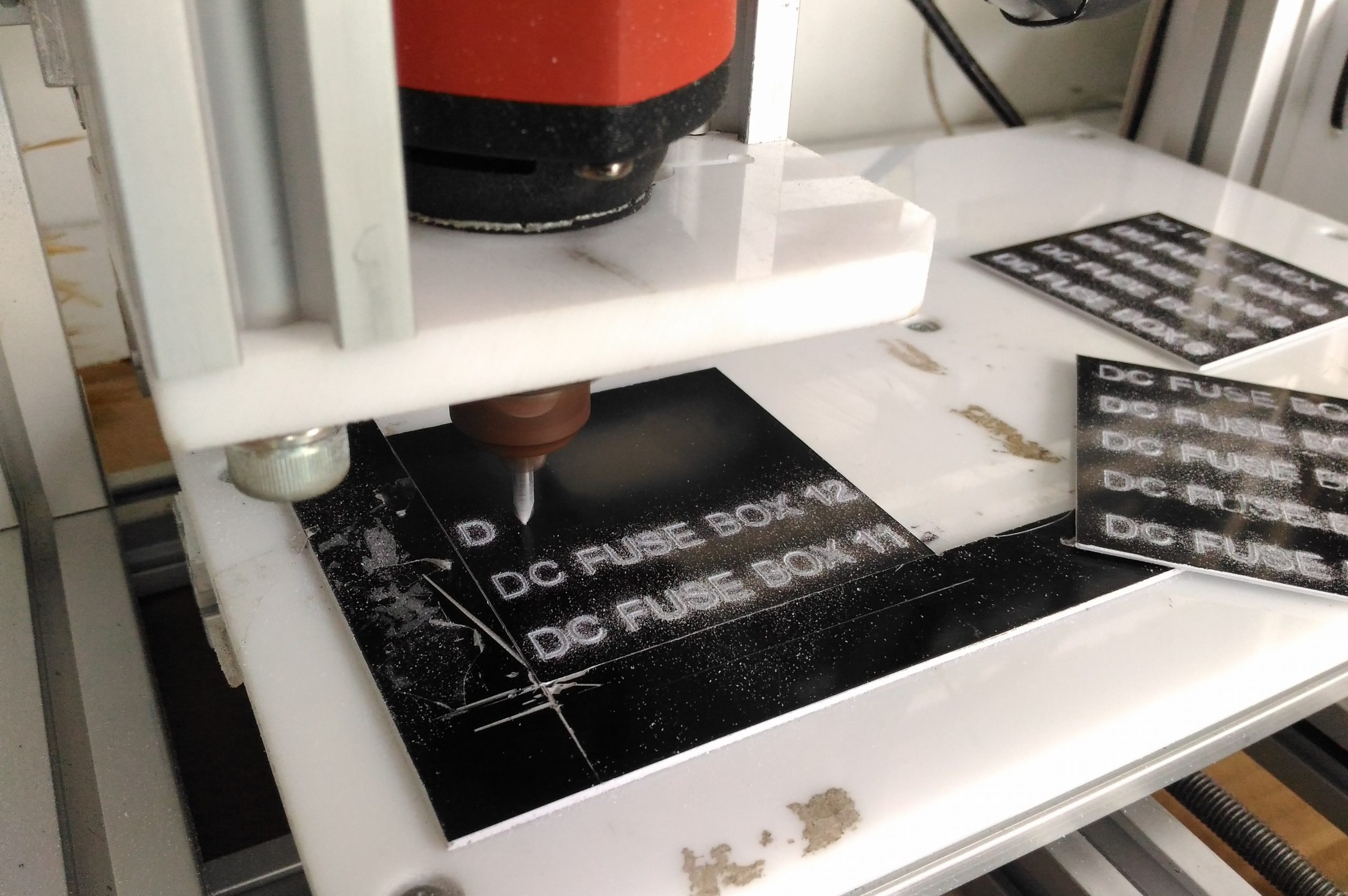

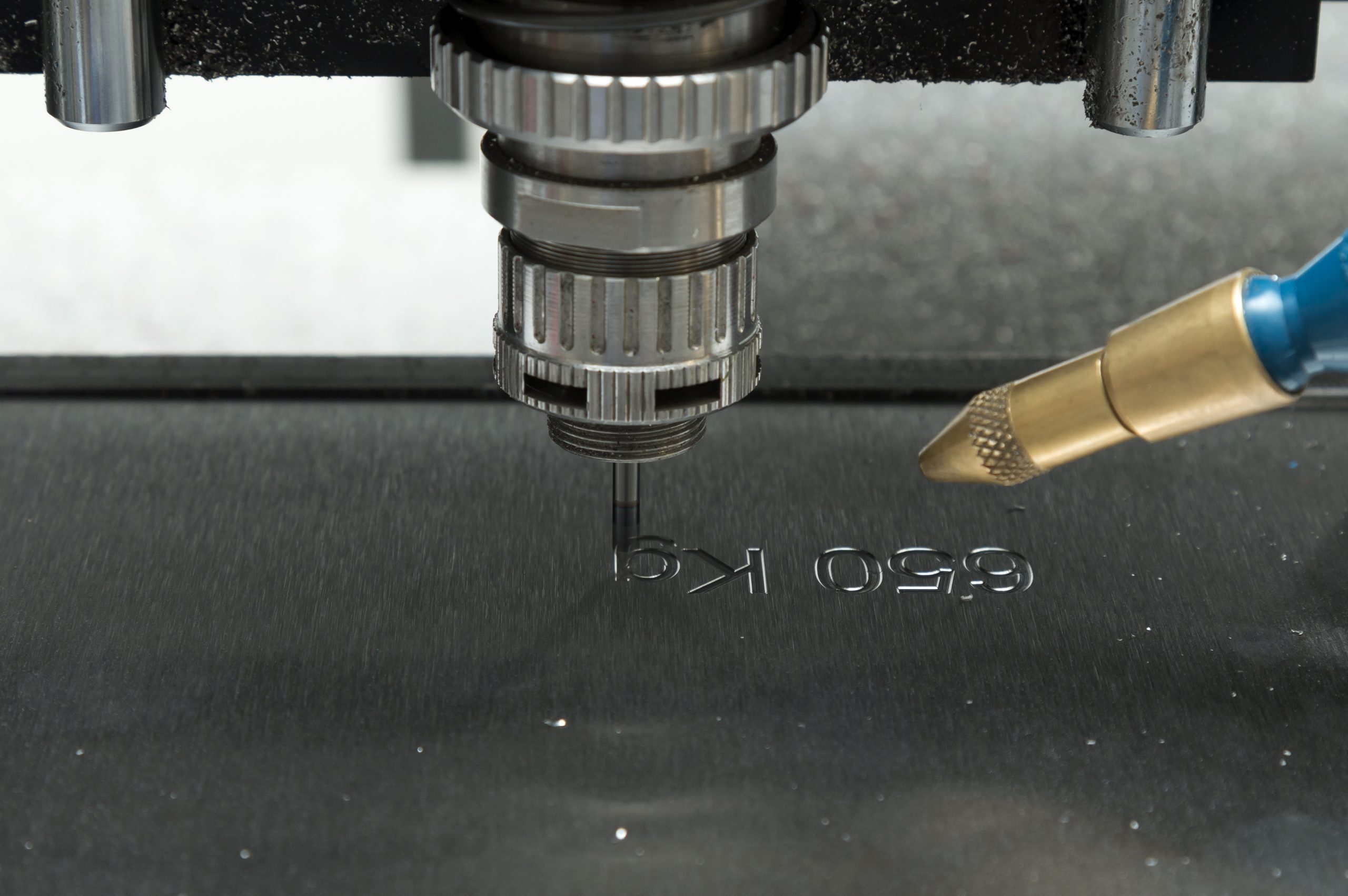

CNC Engraving

Apart from laser technology for engraving and cutting, we also offer such service using a CNC machine which allows us to engrave onto a large and varied range of materials with fantastic precision.

Our CNC machine can engrave sizes up to 600mm x 1100mm, and although we can use this for cutting, we mainly use it for engraving since other services offered are used for cutting. Some materials that we can engrave are brass, aluminium, steel, copper, gold, silver, wood, plastic, acrylic, marble quartz, slate and more.

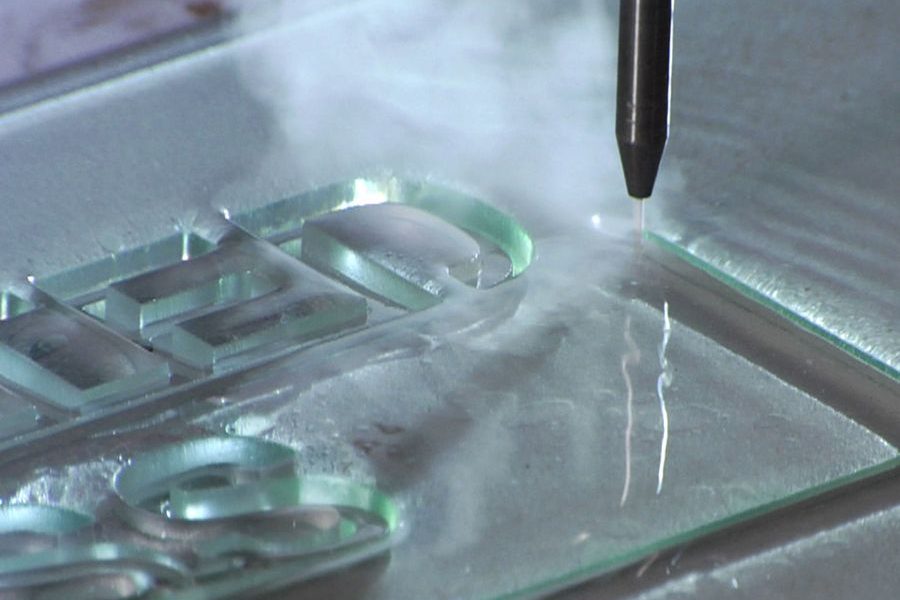

Water-jet Cutting

Using a water jet CNC machine, one can quickly cut metal, marble, ceramic and plastic parts from sheet materials using a high-pressure stream of water and abrasive sand.

Our water-jet machine can cut areas up to 1500mm x 1750mm. It is used mainly to cut squares, circles and any other abstract shape or design required on different materials. Water-jet machines can cut more than 50+ materials: stainless steel, brass, copper, iron, marble, travertine, gres tiles, ceramic tiles, glass, plastic, jablo and much more. Regarding thickness, it can cut from 30mm up to 200mm and achieve a high-quality finish, but it all depends on the material in use.

Plasma Cutting

Plasma CNC machine can only cut metals since it requires a conductive material. Compared with a laser machine, plasma can cut thicker metals.

Our plasma machine can cut areas up to 1500mm x 1750mm. It is used mainly to cut awards, house names & numbers and metal sheets according to the client designs. Regarding thickness, it can cut up to 50mm and achieve a high-quality finish, but it all depends on the metals in use.

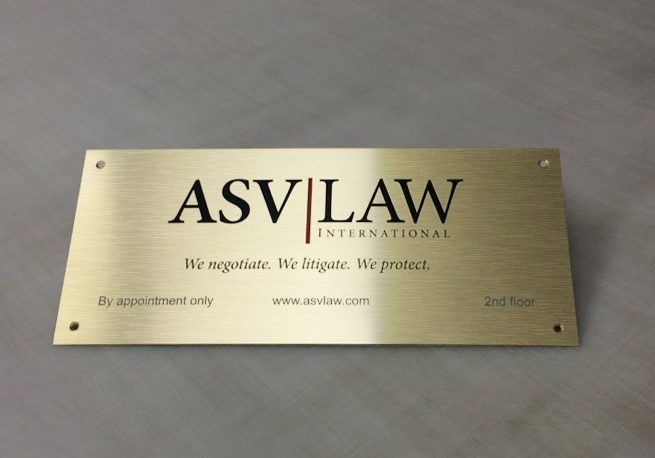

Sublimation Printing

We offer a sublimation printing service for mostly any design one desires. For sublimation printing, one can use different materials such as glass, ceramic, metal, fabric and specific sublimation materials such as aluminium, marble, porcelain and wood. To achieve this, we use special sublimation paper, printers and ink with a maximum printing size of 29cm x 42cm. Lately, we have invested in a new sublimation technology that can print in white colour. Using this technology helps us print special effects and backgrounds and satisfy the need of customers who wish to print in white.

We use the sublimation process in our day to day work to print on mugs, glass awards, plates, ceramic tiles, particular sublimation lava stone and wood portraits for photos and aluminium plates which are available in the following colours silver, gold, copper, white, silver brushed, gold brushed & copper brushed

3D Printing

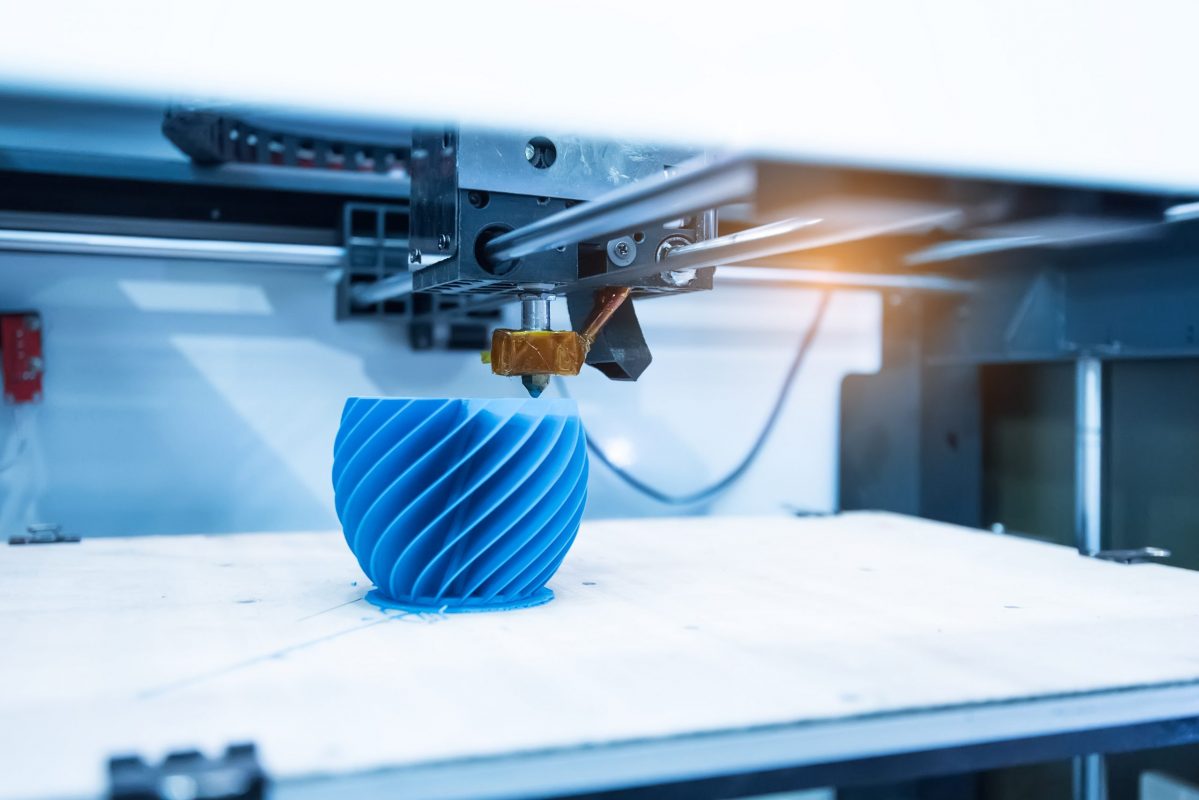

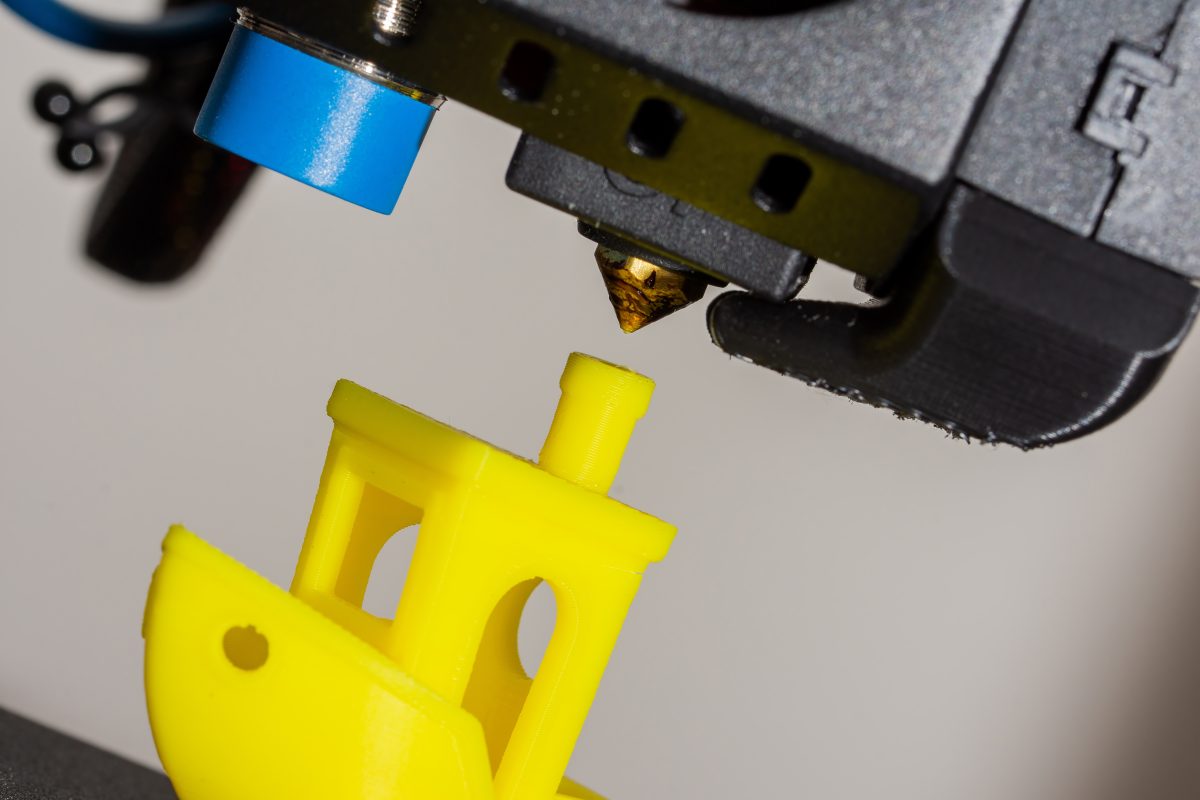

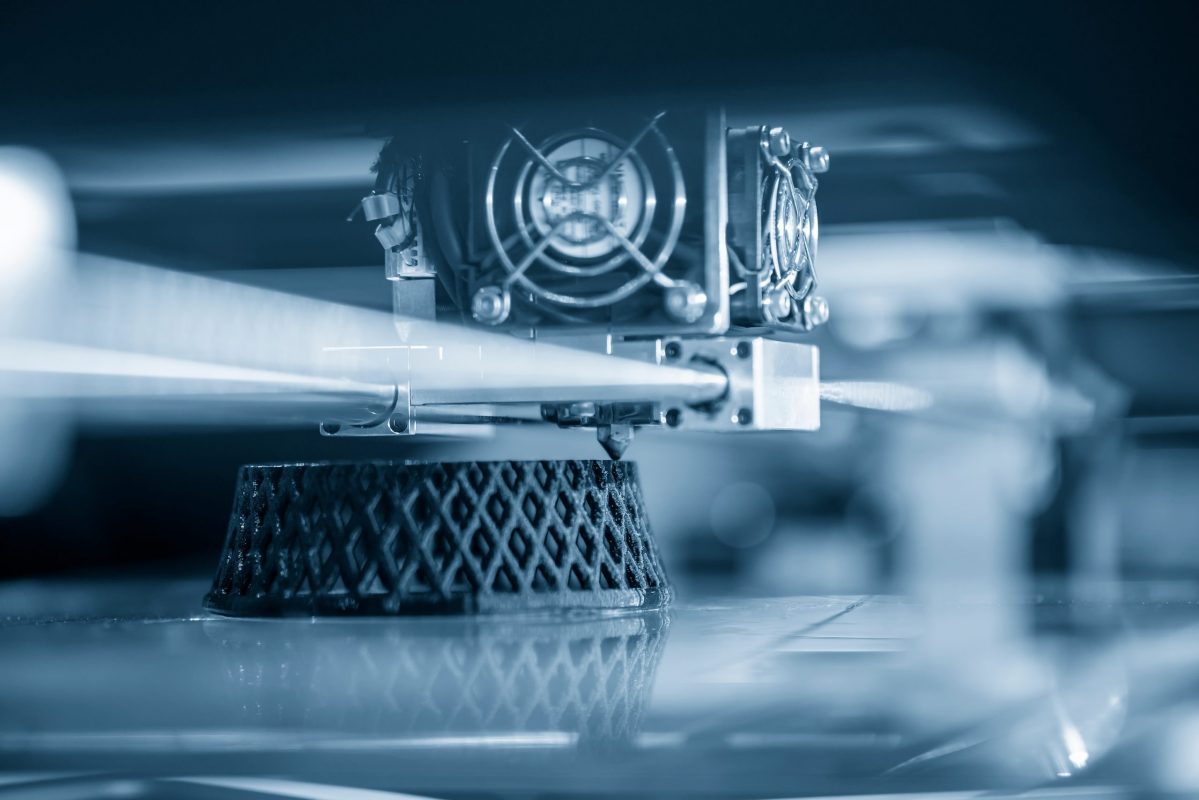

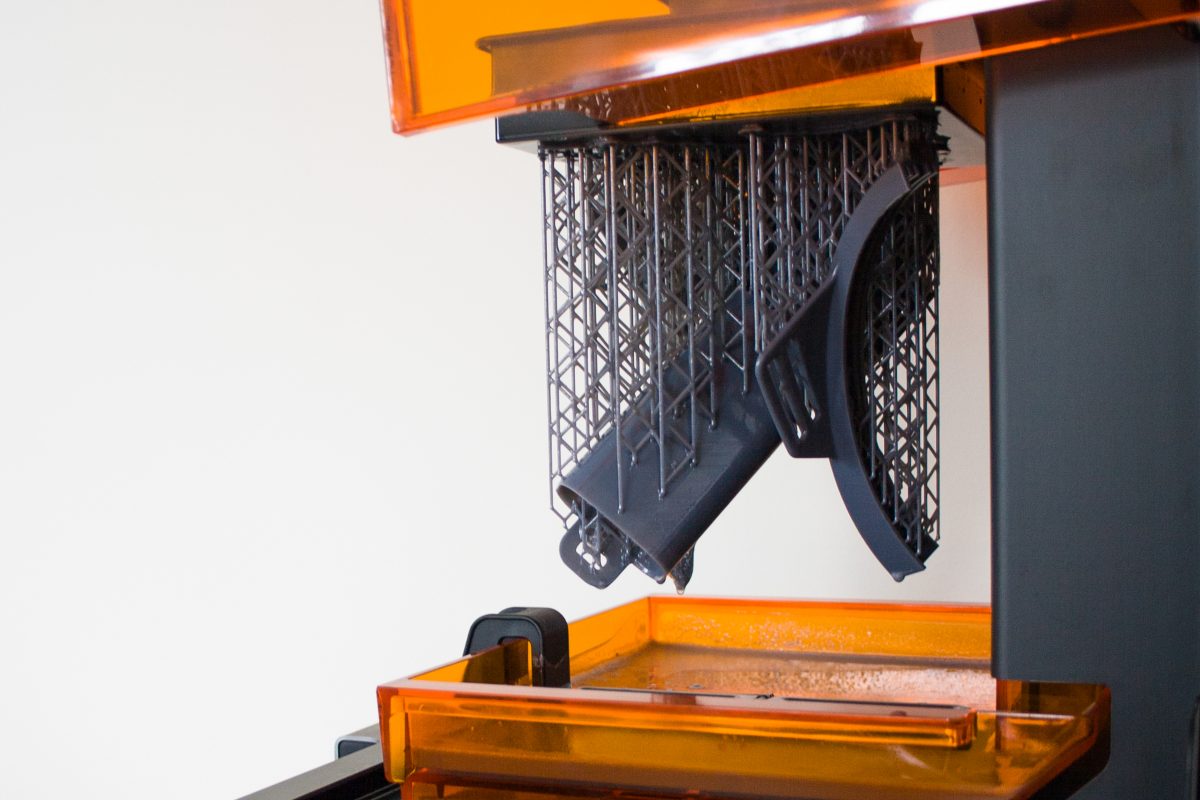

Lately, we have invested heavily in 3D printing technology since this helps us bring our customers ideas to life. Today we offer two different 3D printing technologies.

FDM 3D Printing: We use this technology to print medium to large objects and designs. Printing starts with a string of plastic called a filament, which is melted through a hot end nozzle and deposited on the build plate. The printer prints each layer on top of the previous layer until printing all available layers. The maximum print that our printer can achieve is 220mm x 220mm x 250mm. The print quality in such technology is quite optimal. However, it would still require an amount of finishing, such as filler coating, sanding and painting, to achieve the best result possible, but this all depends on the level of detail required.

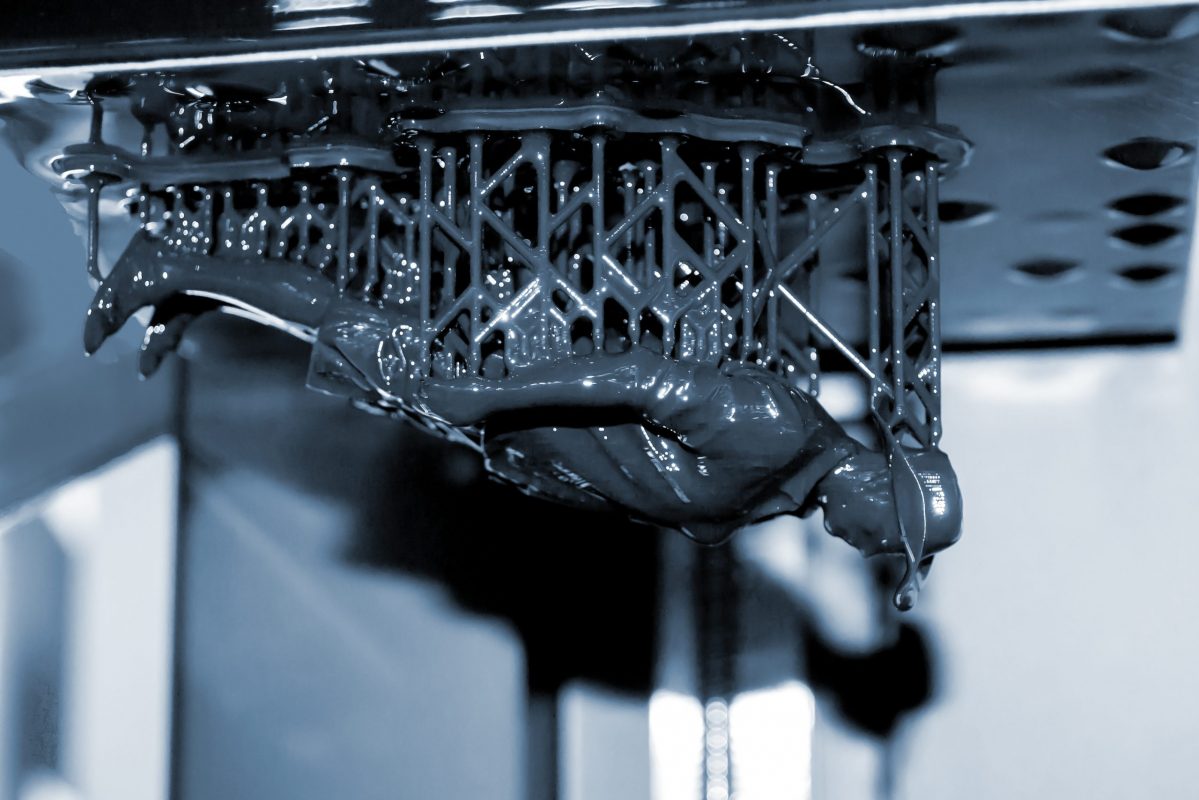

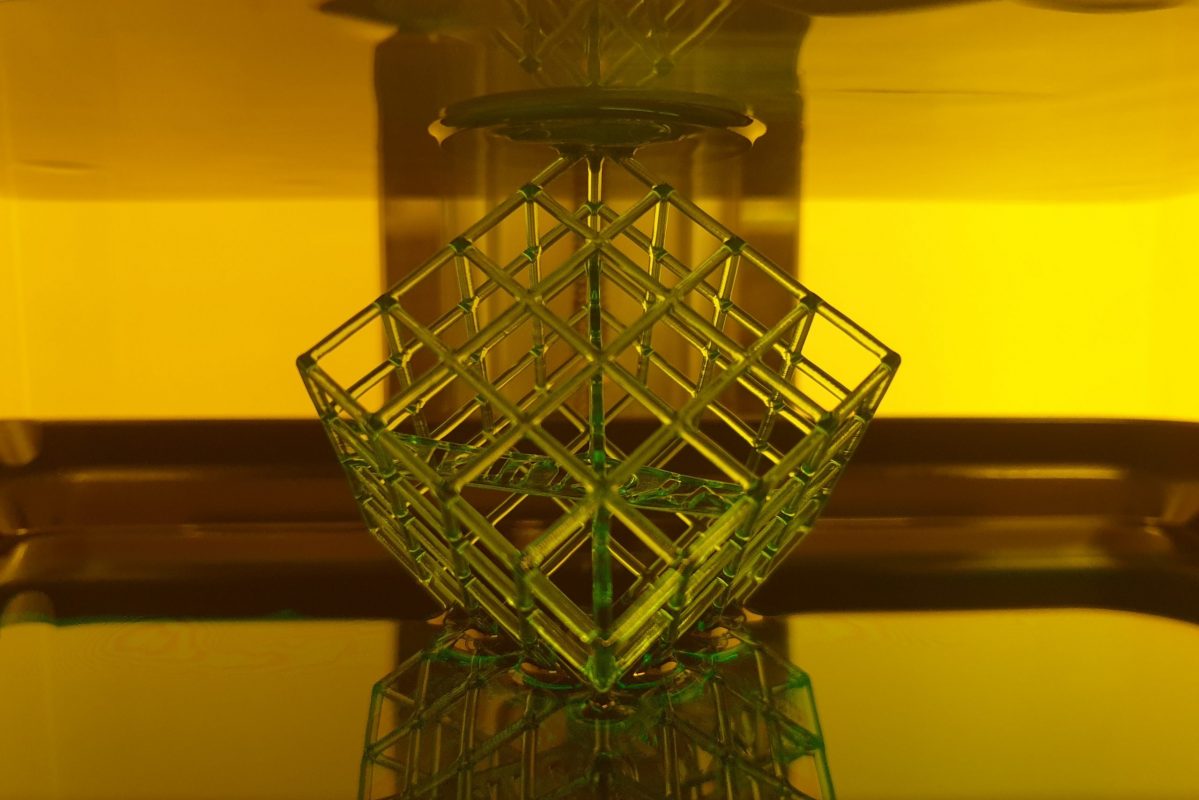

SLA 3D Printing: Stereolithography 3D Printing (SLA) is used to print small to medium objects, which requires a very high level of detail and a smooth finish. Unlike FDM printers, an SLA printer prints using light to cure liquid resin into solid layers. After each layer, the printer bed rises slightly to cure the next layer and continues the same process until printing all layers. This process allows achieving an excellent detail print, far more than a filament printer can produce. Our printers’ maximum print is 140mm x 90mm x 165mm, and the amount of finishing required is little to none, only colour painting if needed.

Mould Casting

We’ve been offering casting service from the beginning of Marindex Trophies. This service goes even earlier since we use this process in our day to day work in the Jewellery business. The casting process starts with a mould containing a hollow cavity of the desired design or shape. Liquid material is then poured and allowed to solidify before opening the mould. One could either use cold or hot casting to perform such a process.

Material varies depending on the requirement of the product, but some materials used are zinc, copper, bronze, gold, silver, resin, stone with reinforced fibre mesh and more. There is no limit in size in such a process as we have done small objects such as rings & figurines and even large objects such as statues.

Economy Trophies

Economy Trophies Luxury Trophies

Luxury Trophies Resin Awards

Resin Awards Glass Awards

Glass Awards